Leather production is a process in which the raw skin is turned into leather - a versatile material used in a number of areas such as clothing, footwear, furniture, holy utensils, car upholstery and more.

The leather production process includes several stages including: cleaning, processing, dyeing, finishing, cutting and sewing.

Cleaning: the leather is soaked in water and then in lime, the soaking cleans the leather. The skin is then softened with the use of enzymes and salting and acidification in order to preserve the skin.

Processing: There are several processing methods and each method greatly affects the quality and price of the leather as well as the nature of its use.

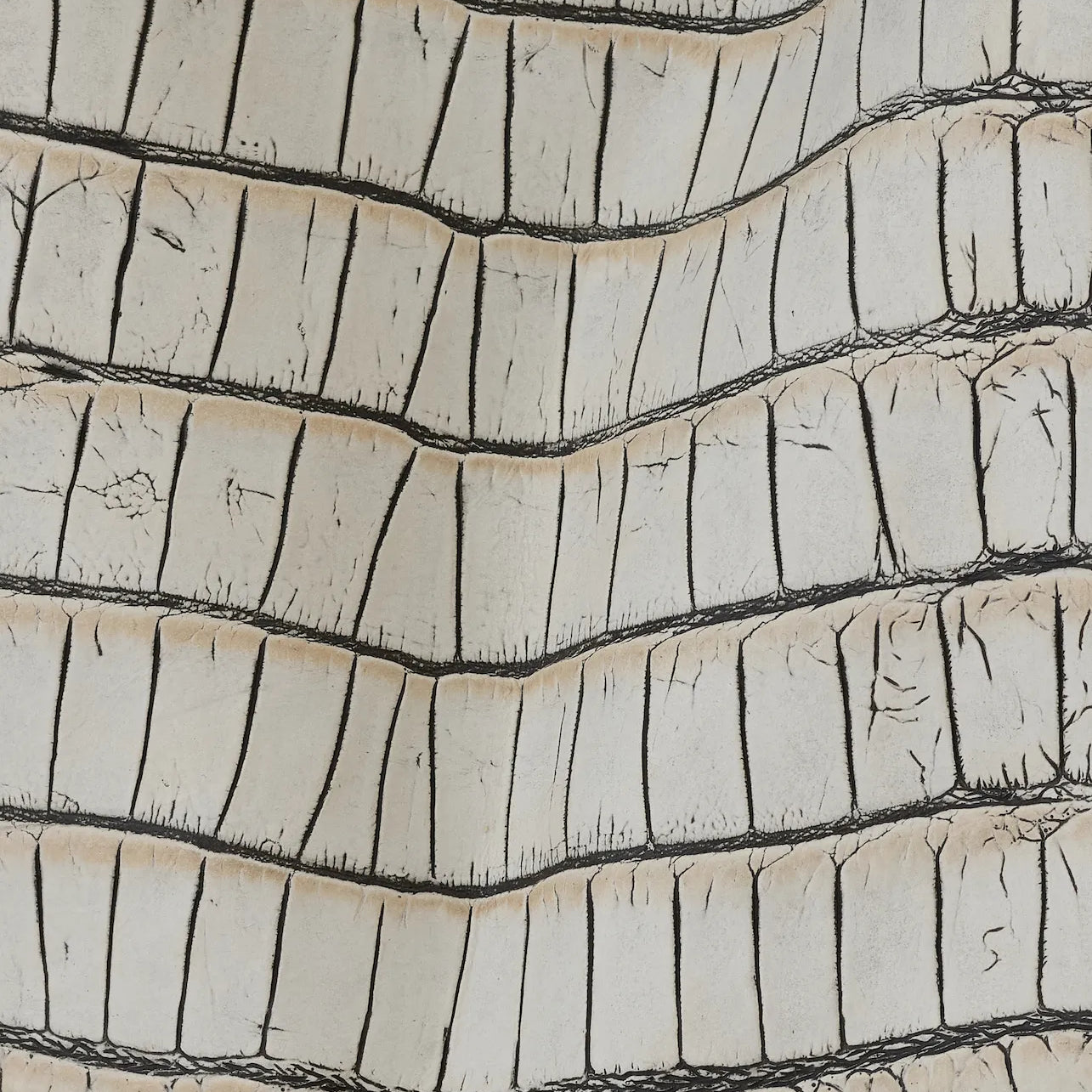

1) Vegetable tanning: the oldest method of processing leather. The leather is processed with a plant-based compost mixture (mainly containing tannin), for 6 months. The vegetable leather is the most expensive and least common of all. The vegetable processing preserves the "breathing" properties of the leather even after the processing. Thanks to this, it can be shaped by softening it with a water-based glue mixture, whose function is to stabilize the leather and prevent it from softening if it gets wet afterwards. This technique is used to make traditional Venetian masks. The vegetable-processed leather also absorbs fat, and is able to "tan" when not protected from light.

2) Processing with chrome: the most common processing method today. The method involves the use of chromium salts, a faster process than plant processing. Chrome processing yields soft, flexible leather in a variety of colors.

3) Synthetic processing: a method that includes the use of synthetic materials. A relatively new method that is gaining more and more popularity thanks to the speed with which the processing of the leather takes place, and thanks to its efficiency.

*Interesting fact - the word "bursa", originally from the Latin language: "bursa" which means bag, purse. Like the Greek word "birsa", which means "skin" (also the Hebrew word "tanner" - leather worker, originates from the same word). After that, the word became a description of a leather bag containing money, similar to the word Purse in English.

Dyeing: carried out by several methods: spraying, soaking dyeing, manual dyeing. In addition, there are several types of pigments: acid pigment, direct pigment or reactive pigment.

Finishing: At this stage the polishing, coating, polishing, stamping and finishing of the edges of the leather is done.

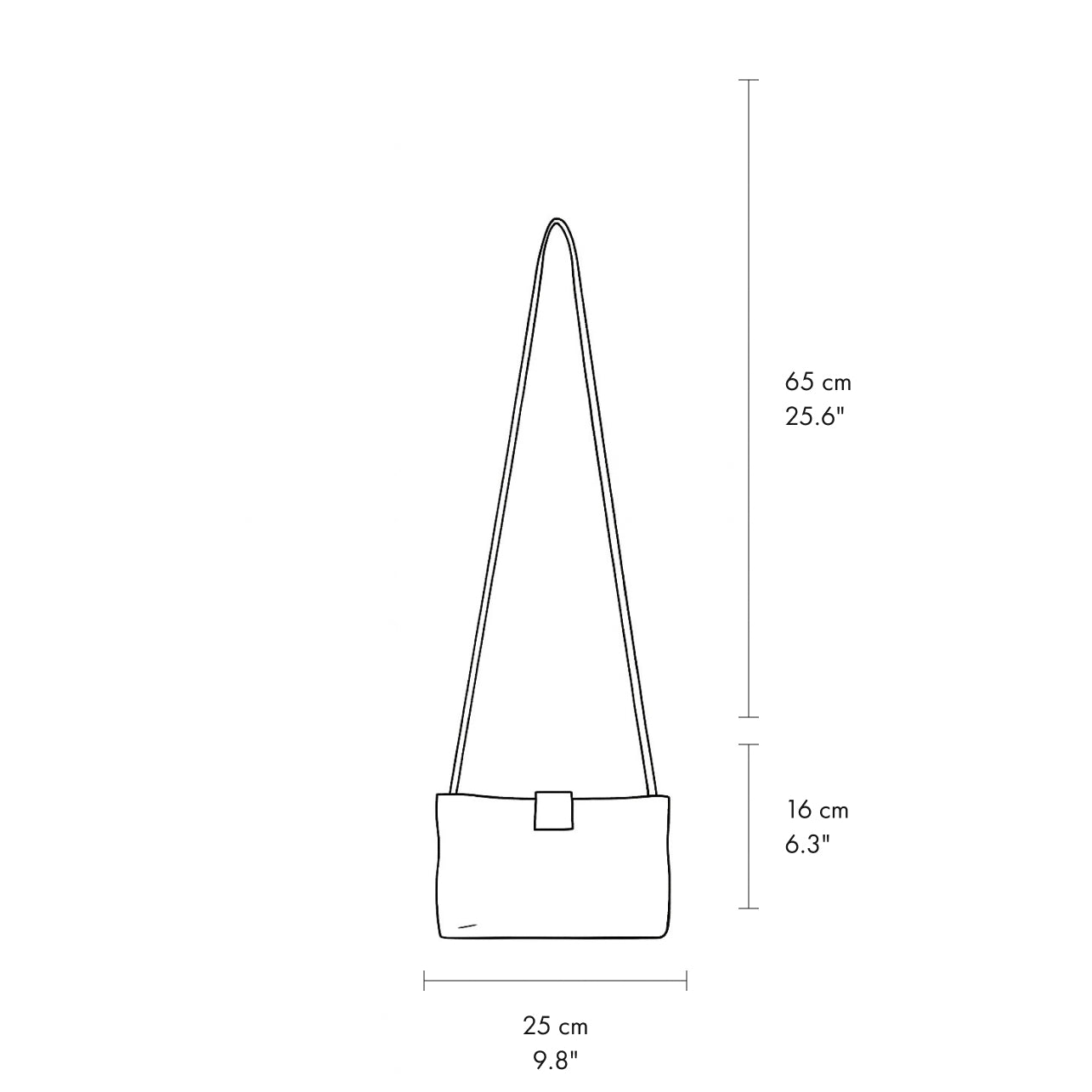

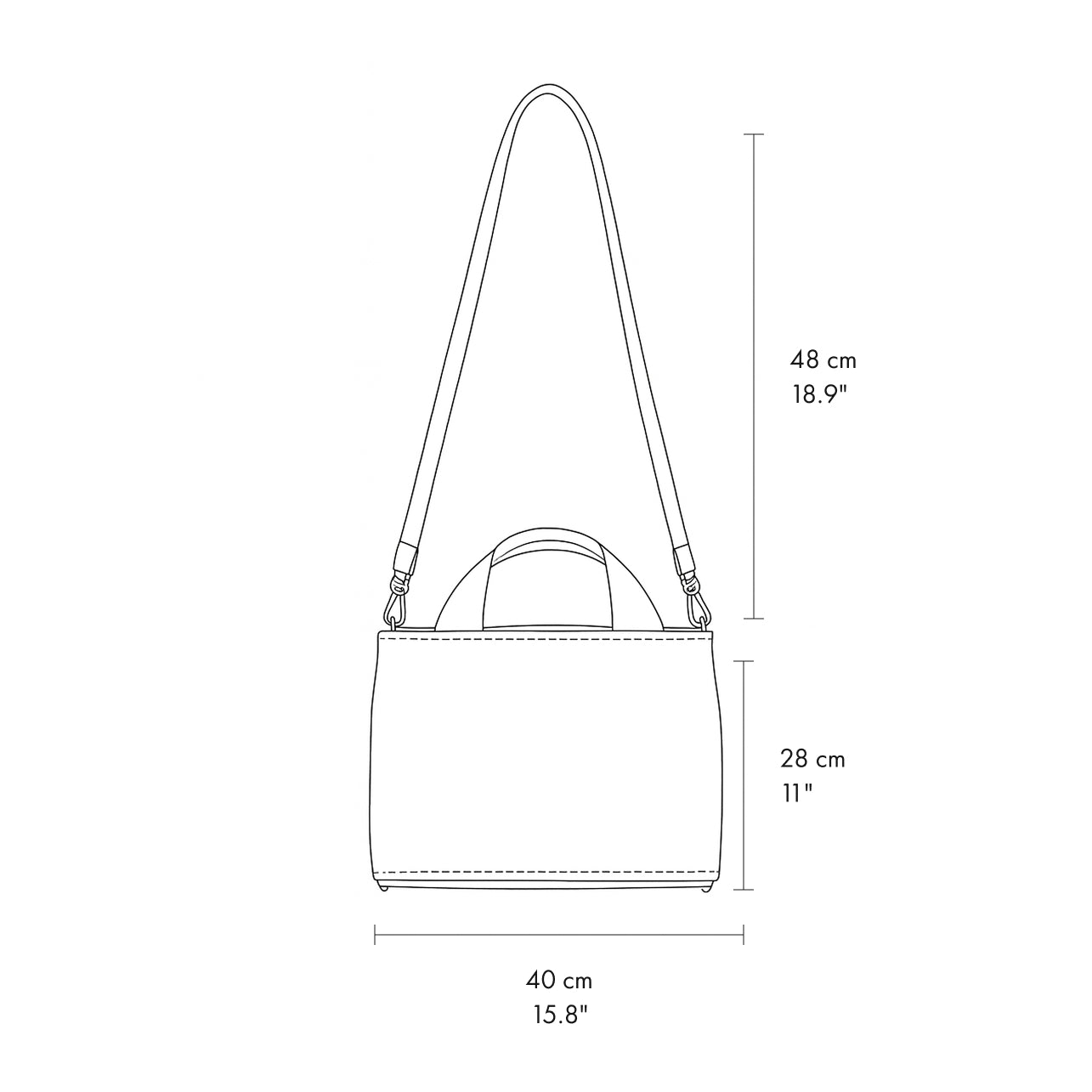

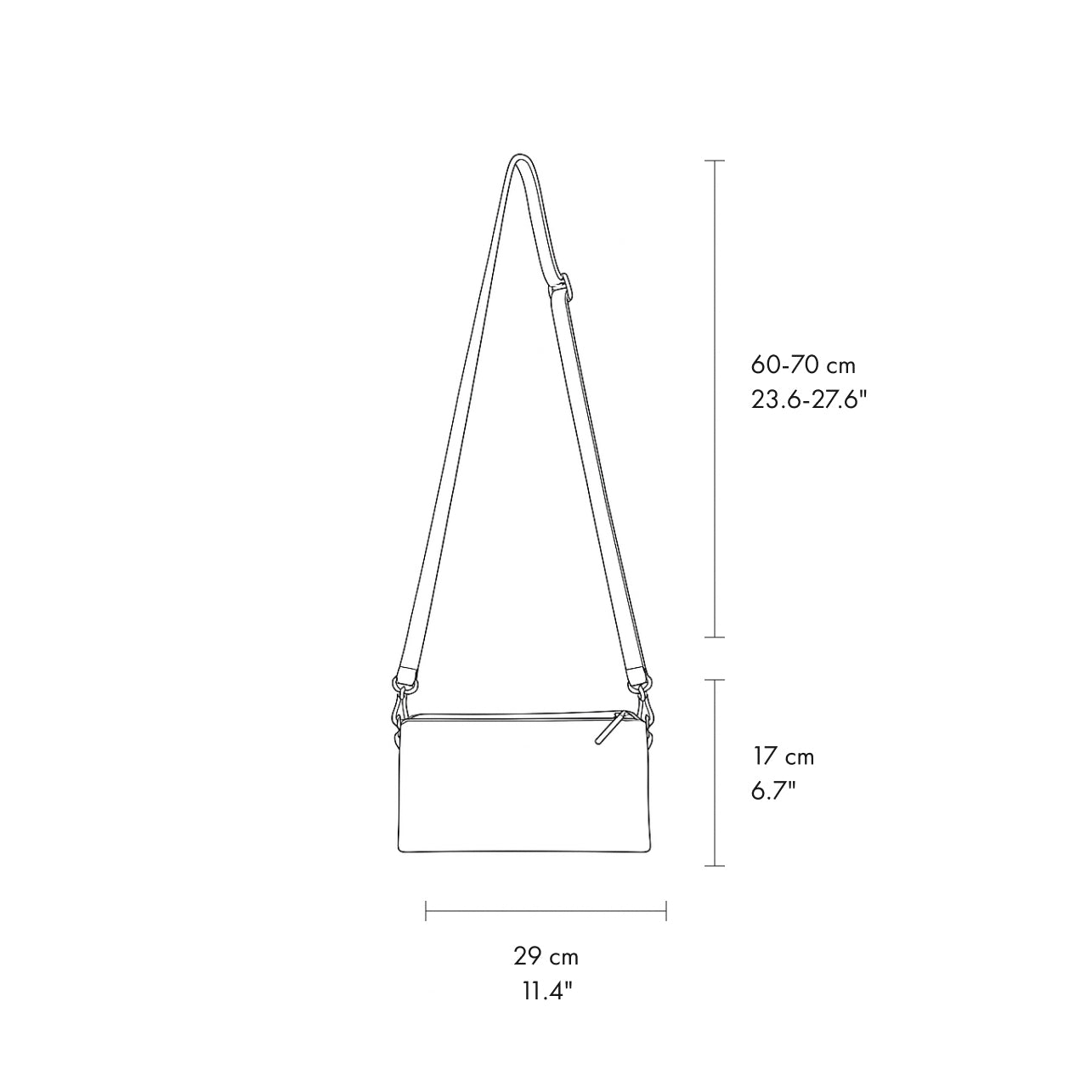

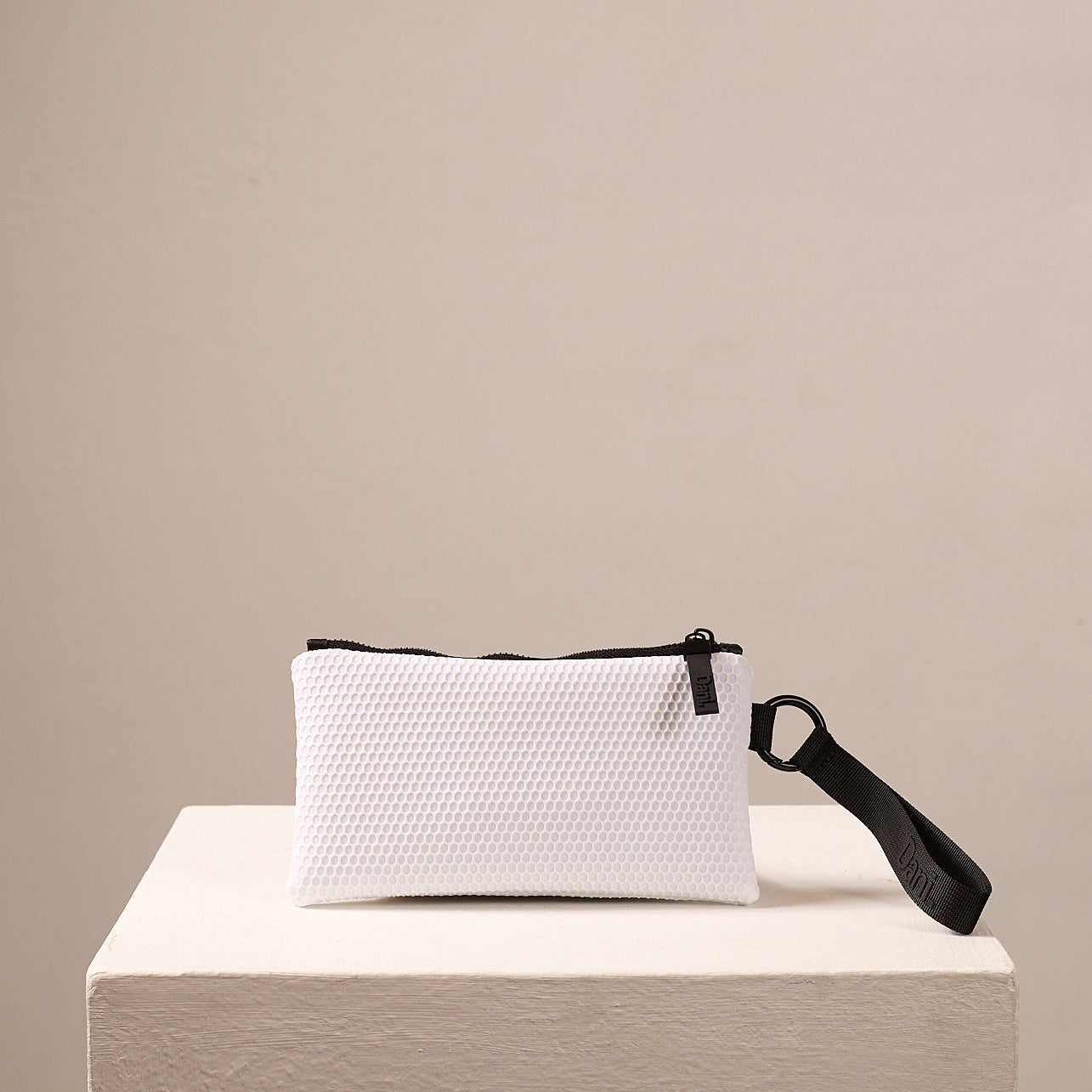

Cutting and sewing: at this stage the leather is ready for the designer's work, the leather compared to other fabrics requires different cutting and processing methods, including softening and dyeing the edges, creating phases and more. Leather sewing is also unusual, requiring more massive machines, and the use of special techniques. You can see a bit about the design and development process here at Daniela Lehbi.

What are the differences between the types of skins and how can you tell the difference? Go to the article we have prepared for you that will put you in order in the whole leather world. >> Types of skins

Comments

hacked By LoXen7